SMC Insulating Sheet

Product Instruction

Sheet molding compound is a type of reinforced polyester containing glass fibers. The fibers, which are typically 1” or greater in length, are suspended in a bath of resin – usually epoxy, vinyl ester, or polyester.

Application

Mainly used in electric power control cabinet,distribution box. switchboard and other Other electrical structural components. It has the excellent electric performance, excellent flame resistance performance,excellent mechanical strength, excellent smooth surface , excellent size stability.

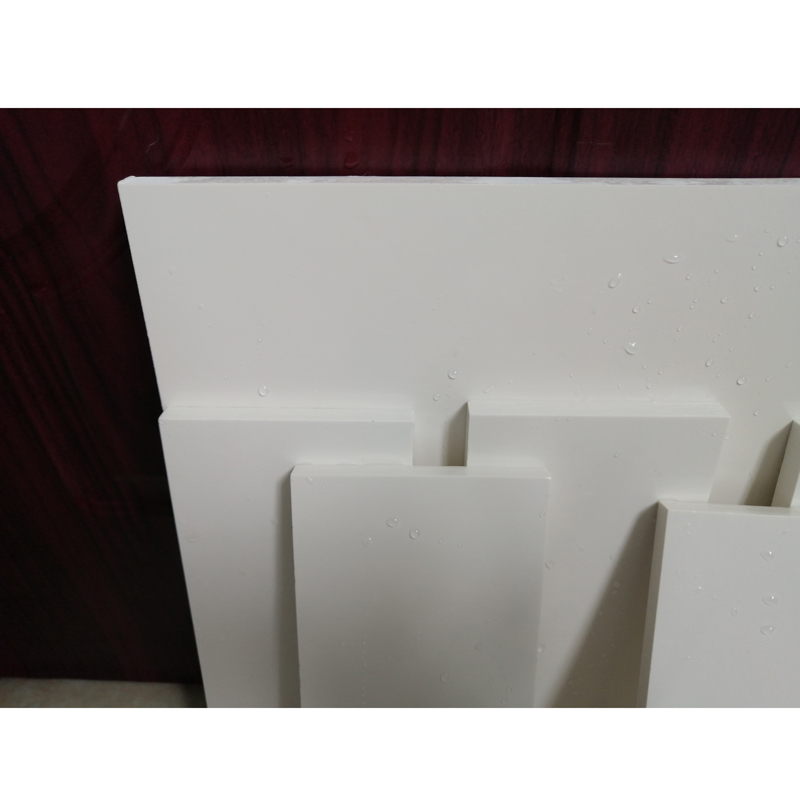

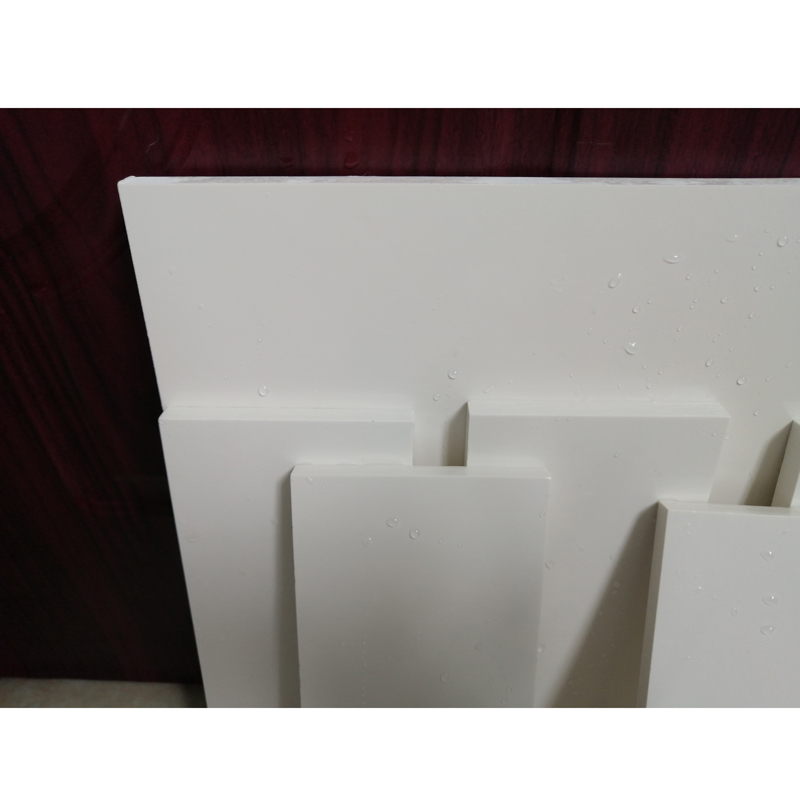

Product pictures

Main Technical Date

|

Property |

Unit |

Method |

Standard value |

Typical value |

|

Density |

g/cm3 |

ISO62(Method 1) |

_ |

1.85 |

|

Water absorption 2.0mm in thickness |

% |

ISO62(Method 1) |

_ |

≤0.30 |

|

Flexural strength perpendicular to laminations - under normal room temperature |

MPa |

ISO178:2001 |

_ |

≥130 |

|

Flexural strength perpendicular to laminations - under 130℃ |

MPa |

ISO178:2001 |

_ |

≥90 |

|

Tensile strength |

MPa |

ISO527 |

_ |

≥50 |

|

Compressive Strength under 130℃ |

MPa |

ISO604:2002 |

_ |

≥150 |

|

Temperature of deflection under load Tf=1.8MPa |

℃ |

ISO75-2:2003 |

_ |

≥220 |

|

Temperature index(TI) Long-term heat resistance temperature |

℃ |

IEC60216 |

_ |

155 |

|

Insulation Resistance |

Ω |

IEC60167:1964 |

_ |

≥1.0x1012 |

|

Insulation resistance after 24 h water immersion |

Ω |

IEC60167:1964 |

_ |

≥1.0x1010 |

|

Dielectric strength step by step in oil at 23℃,Thickness 1-3mm |

kV/mm |

IEC60243 |

_ |

≥12.0 |

|

Relative Permittivity(50Hz) |

_ |

IEC60250 |

_ |

≤4.5 |

|

Dielectric dissipation factor(50Hz) |

_ |

IEC60250 |

_ |

≤0.015 |

|

Arc Resistance |

S |

IEC61621 |

_ |

≥180 |

|

Tracking Resistance(CTI) |

V |

IEC60112 |

_ |

≥600 |

|

Flammability |

Class |

UL94 |

_ |

V-0 |

FAQ

Q1: Are you trading company or manufacturer?

We are the leading manufacturer of electrical insulating composite,We have been engaged in manufacturer thermoset rigid composite since 2003.Our capacity is 6000TONS/year.

Q2: Samples

Samples are free,you only need to pay for the shipping charge.

Q3: How do you guarantee the quality of mass production?

For appearance,size and thickness: we will make full inspection before packing.

For performance quality: We use a fixed formula, and will be regular sampling inspection, we can provide product inspection report before shipment.

Q4: Delivery time

It depends on order quantity.Generally speaking, the delivery time will be 15-20 days.

Q5: Package

We will use professional craft paper to package on plywood pallet.if you have special package requirements, we will pack as your need.

Q6: Payment

TT, 30% T/T in advance ,balance before shipment.We also accept L/C.