Factory wholesale Fr4 Epoxy Sheet - 3250 Epoxy Glassfiber Laminated Sheet – Xinxing

Factory wholesale Fr4 Epoxy Sheet - 3250 Epoxy Glassfiber Laminated Sheet – Xinxing Detail:

Product Description

This product is a laminated product which made with the chemical treatment electrical purposed alkali-free glass cloth as the backing material,by hot pressing with high Tg epoxy resin as binder.It has high mechanical strength under high temperature,with good electrical stability under high humidity.The thermostability is grade F,suitable for all kinds of motor, electric appliances,electronic and other fields.

Features

1.Good electrical stability under high humidity;

2.High mechanical strength under high temperature,the mechanical strength retention rate≥50% under 180℃;

3.Moisture resistance;

4.Heat resistance;

5.Temperature resistance:Class H,180℃

Main Performance Index

In accordance with GB/T 1303.4-2009 electrical thermosetting resin industrial hard laminates – Part 4: epoxy resin hard laminates.

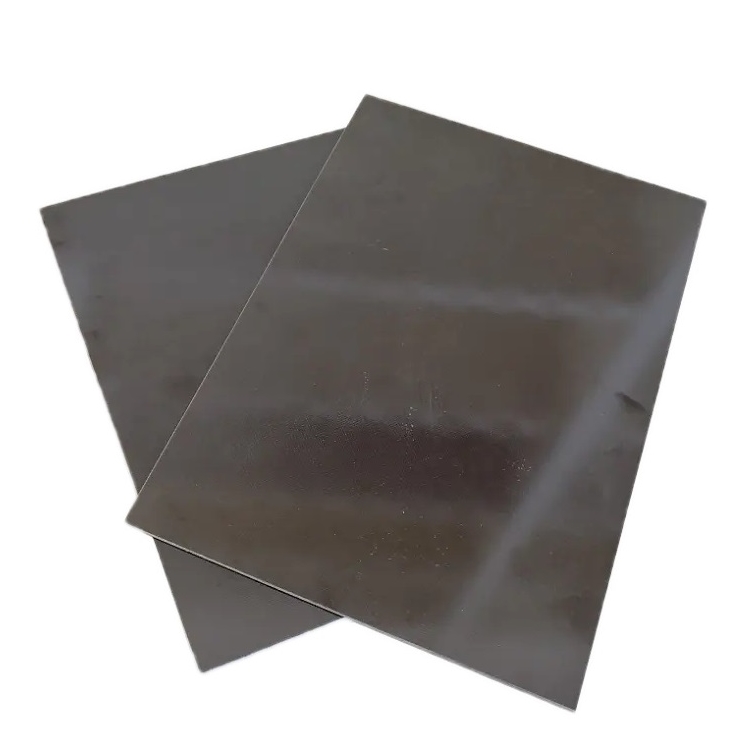

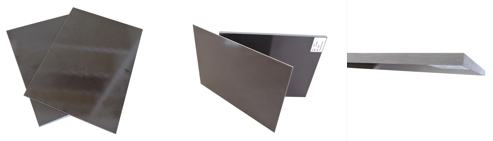

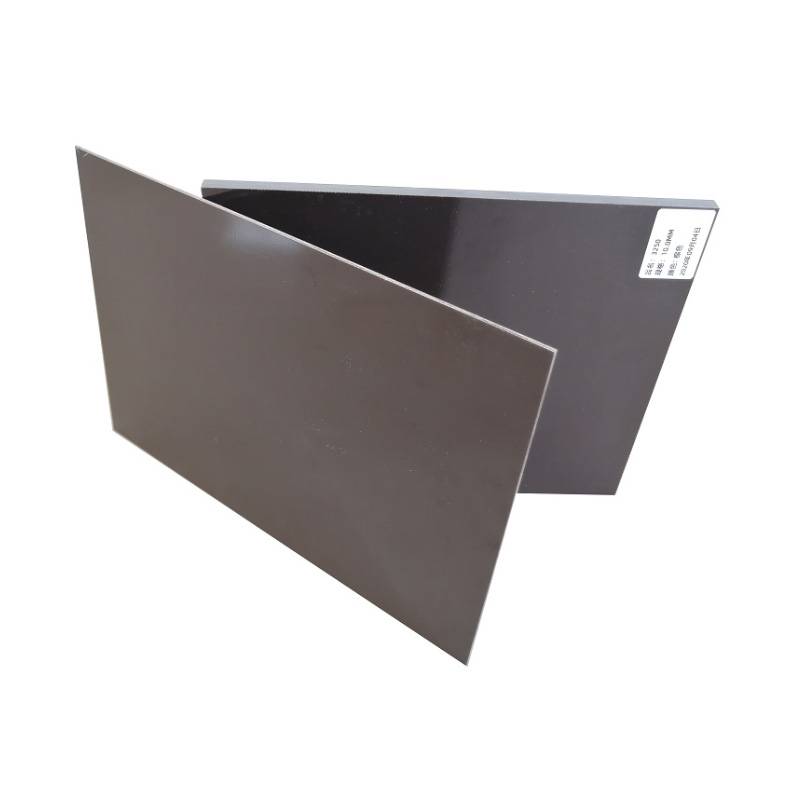

Appareance: the surface should be flat, free of bubbles, pits and wrinkles, but other defects that do not affect the use are allowed, such as: scratches, indentation, stains and a few spots.The edge shall be cut neatly, and the end face shall not be delaminated and cracked.

Application

Suitable for all kinds of motor, electric appliances,electronic and other fields.

Main Performance Index

| NO. | ITEM | UNIT | INDEX VALUE | |||

| 01 | Density | g/cm³ | 1.8-2.1 | |||

| 02 | Water absorption | % | <0.5 | |||

| 03 | Vertical bending strength | Normal | Lengthways | MPa | ≥450 | |

| ≥380 | ||||||

| Lateral | ||||||

| 180±2℃ | Lengthways | ≥250 | ||||

| ≥190 | ||||||

| Lateral | ||||||

| 04 | Impact strength(Charpy type) | No Gap | Lengthways | KJ/m² | ≥180 | |

| Lateral | ≥137 | |||||

| 05 | compression strength | Vertical | MPa | ≥500 | ||

| Parallel | ≥250 | |||||

| 06 | Tensile strength | Lenthways | MPa | ≥320 | ||

| Lateral | ≥300 | |||||

| 07 | Bond strength | N | ≥7200 | |||

| 08 | Vertical electric strength(in oil of 90℃±2℃ 1min) | 1mm | MV/m | ≥17.0 | ||

| 2mm | ||||||

| ≥14.9 | ||||||

| 3mm | ||||||

| ≥13.8 | ||||||

| 09 | Parallel breakdown voltage(in oil of 90℃±2℃) | KV | ≥40 | |||

| 10 | Relative dielectric constant(50Hz) | - | ≤5.5 | |||

| 11 | dielectric dissipation factor(50Hz) | - | ≤0.04 | |||

| 12 | Parallel insulation resistance | Normal | MΩ | ≥5.0×106 | ||

| After soaking for 24 hours | ≥5.0×104 | |||||

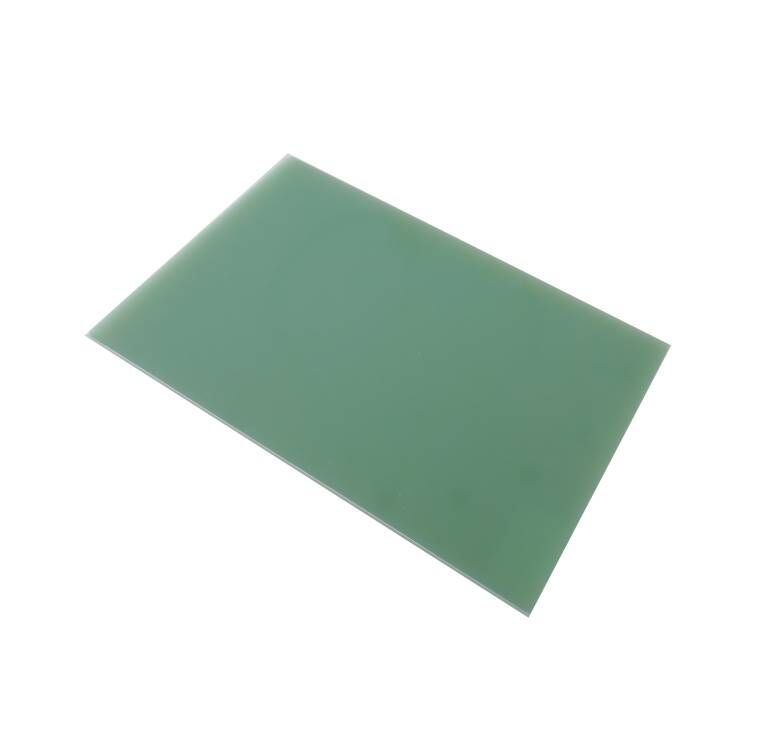

Product detail pictures:

Related Product Guide:

We aim to find out high quality disfigurement in the generation and provide the most effective services to domestic and abroad clients wholeheartedly for Factory wholesale Fr4 Epoxy Sheet - 3250 Epoxy Glassfiber Laminated Sheet – Xinxing, The product will supply to all over the world, such as: Southampton, Bangladesh, Manchester, If you are for any reason unsure which product to select, do not hesitate to contact us and we will be delighted to advise and assist you. This way we will be providing you with all the knowledge needed to make the best choice. Our company strictly follows "Survive by good quality, Develop by keeping good credit. " operation policy. Welcome all the clients old and new to visit our company and talk about the business. We are looking for more and more customers to create the glorious future.

We are old friends, the company's product quality has been always very good and this time the price is also very cheap.