China Factory for Fiberglass Panel Sheets - 3250 Epoxy Glassfiber Laminated Sheet – Xinxing

China Factory for Fiberglass Panel Sheets - 3250 Epoxy Glassfiber Laminated Sheet – Xinxing Detail:

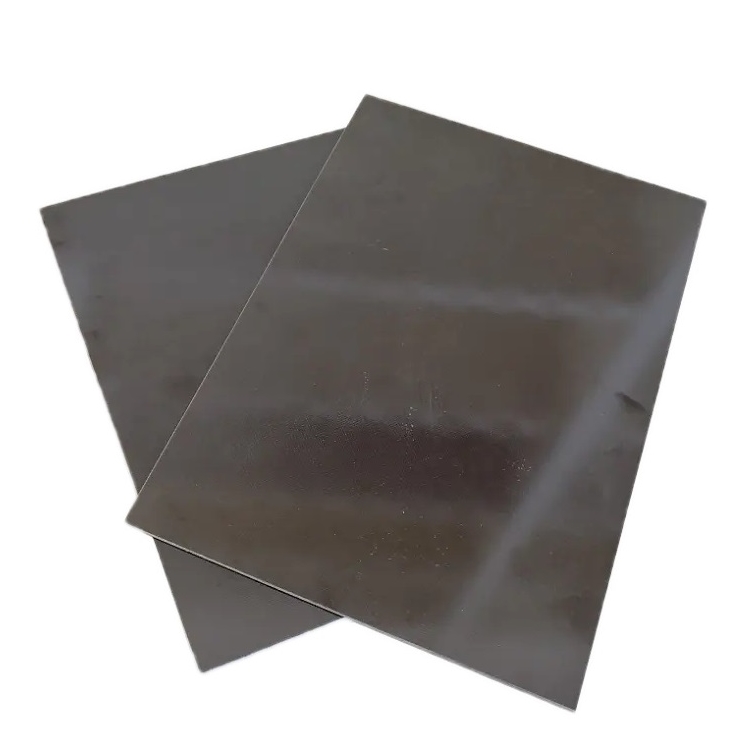

Product Description

This product is a laminated product which made with the chemical treatment electrical purposed alkali-free glass cloth as the backing material,by hot pressing with high Tg epoxy resin as binder.It has high mechanical strength under high temperature,with good electrical stability under high humidity.The thermostability is grade F,suitable for all kinds of motor, electric appliances,electronic and other fields.

Features

1.Good electrical stability under high humidity;

2.High mechanical strength under high temperature,

the mechanical strength retention rate≥50% under 180℃;

3.Moisture resistance;

4.Heat resistance;

5.Temperature resistance:Grade H

Main Performance Index

In accordance with GB/T 1303.4-2009 electrical thermosetting resin industrial hard laminates – Part 4: epoxy resin hard laminates.

Appareance: the surface should be flat, free of bubbles, pits and wrinkles, but other defects that do not affect the use are allowed, such as: scratches, indentation, stains and a few spots.The edge shall be cut neatly, and the end face shall not be delaminated and cracked.

Application

Suitable for all kinds of motor, electric appliances,electronic and other fields.

Main Performance Index

| NO. | ITEM | UNIT | INDEX VALUE | |||

| 1 | Density | g/cm³ | 1.8-2.0 | |||

| 2 | Water absorption Rate | % | ≤0.5 | |||

| 3 | Vertical bending strength | Normal | Lengthway | MPa | ≥450 | |

| Horizontal | ≥380 | |||||

| 180±5℃ | Lengthway | ≥250 | ||||

| Horizontal | ≥190 | |||||

| 4 | Impact strength (charpy type) | No gap | Lengthway | KJ/m² | ≥180 | |

| Horizontal | ≥137 | |||||

| 5 | Compression strength | Lengthway | MPa | ≥500 | ||

| Horizontal | ≥250 | |||||

| 6 | Tensile strength | Lengthway | MPa | ≥320 | ||

| Horizontal | ≥300 | |||||

| 7 | Vertical electric strength (in oil of 90℃±2℃) |

1mm | KV/mm | ≥17.0 | ||

| 2mm | ≥14.9 | |||||

| 3mm | ≥13.8 | |||||

| 8 | Parallel breakdown voltage(1 min in oil of 90℃±2℃) | KV | ≥40 | |||

| 9 | Dielectric dissiption factor(50Hz) | - | ≤0.04 | |||

| 10 | Parrallel Insulation Resistance | Normal | Ω | ≥1.0×1012 | ||

| After soaking for 24hours | ≥1.0×1010 | |||||

Product detail pictures:

Related Product Guide:

We have our own product sales staff, style crew, technical group, QC staff and package staff. We now have strict high quality management procedures for each approach. Also, all of our workers are experienced in printing subject for China Factory for Fiberglass Panel Sheets - 3250 Epoxy Glassfiber Laminated Sheet – Xinxing, The product will supply to all over the world, such as: Ottawa, belarus, Houston, We take measure at any price to attain essentially the most up-to-date gear and procedures. The packing of nominated brand is our a further distinguishing feature. The solutions to assure years of trouble-free service has attracted a great deal customers. The goods are obtainable in improved designs and richer variety, they're produced scientifically of purely raw supplies. It accessible in a variety of designs and specifications for the selection. The newest forms are much far better than the previous one and they're extremely popular with several clients.

The company can think what our think, the urgency of urgency to act in the interests of our position, can be said this is a responsible company, we had a happy cooperation!