Manufacturer of Fiber Insulation Board - 3250 Epoxy Glassfiber Laminated Sheet – Xinxing

Manufacturer of Fiber Insulation Board - 3250 Epoxy Glassfiber Laminated Sheet – Xinxing Detail:

Product Description

This product is a laminated product which made with the chemical treatment electrical purposed alkali-free glass cloth as the backing material,by hot pressing with high Tg epoxy resin as binder.It has high mechanical strength under high temperature,with good electrical stability under high humidity.The thermostability is grade F,suitable for all kinds of motor, electric appliances,electronic and other fields.

Features

1.Good electrical stability under high humidity;

2.High mechanical strength under high temperature,

the mechanical strength retention rate≥50% under 180℃;

3.Moisture resistance;

4.Heat resistance;

5.Temperature resistance:Grade H

Main Performance Index

In accordance with GB/T 1303.4-2009 electrical thermosetting resin industrial hard laminates – Part 4: epoxy resin hard laminates.

Appareance: the surface should be flat, free of bubbles, pits and wrinkles, but other defects that do not affect the use are allowed, such as: scratches, indentation, stains and a few spots.The edge shall be cut neatly, and the end face shall not be delaminated and cracked.

Application

Suitable for all kinds of motor, electric appliances,electronic and other fields.

Main Performance Index

| NO. | ITEM | UNIT | INDEX VALUE | |||

| 1 | Density | g/cm³ | 1.8-2.0 | |||

| 2 | Water absorption Rate | % | ≤0.5 | |||

| 3 | Vertical bending strength | Normal | Lengthway | MPa | ≥450 | |

| Horizontal | ≥380 | |||||

| 180±5℃ | Lengthway | ≥250 | ||||

| Horizontal | ≥190 | |||||

| 4 | Impact strength (charpy type) | No gap | Lengthway | KJ/m² | ≥180 | |

| Horizontal | ≥137 | |||||

| 5 | Compression strength | Lengthway | MPa | ≥500 | ||

| Horizontal | ≥250 | |||||

| 6 | Tensile strength | Lengthway | MPa | ≥320 | ||

| Horizontal | ≥300 | |||||

| 7 | Vertical electric strength (in oil of 90℃±2℃) |

1mm | KV/mm | ≥17.0 | ||

| 2mm | ≥14.9 | |||||

| 3mm | ≥13.8 | |||||

| 8 | Parallel breakdown voltage(1 min in oil of 90℃±2℃) | KV | ≥40 | |||

| 9 | Dielectric dissiption factor(50Hz) | - | ≤0.04 | |||

| 10 | Parrallel Insulation Resistance | Normal | Ω | ≥1.0×1012 | ||

| After soaking for 24hours | ≥1.0×1010 | |||||

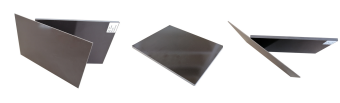

Product detail pictures:

Related Product Guide:

We always stick to the principle "Quality First, Prestige Supreme". We are fully committed to providing our clients with competitively priced quality products, prompt delivery and professional service for Manufacturer of Fiber Insulation Board - 3250 Epoxy Glassfiber Laminated Sheet – Xinxing, The product will supply to all over the world, such as: Israel, Hanover, Luxembourg, Satisfaction and good credit to every customer is our priority. We focus on every detail of order processing for customers till they have received safe and sound solutions with good logistics service and economical cost. Depending on this, our solutions are sold very well in the countries in Africa, the Mid-East and Southeast Asia.

As an international trading company, we have numerous partners, but about your company, I just want to say, you are really good, wide range, good quality, reasonable prices, warm and thoughtful service, advanced technology and equipment and workers have professional training, feedback and product update is timely, in short, this is a very pleasant cooperation, and we look forward to the next cooperation!